What are Nes tools

When a screw does not enter in the hole correctly, it could be due to damage to its thread or that of the component that houses it.

It can happen for various reasons; perhaps the thread has oxidized, or has been dented due to external agents, or has simply been treated or painted and therefore does not allow the screw to slide correctly.

In these cases, having the Nes tool allows you to restore the mechanical functioning of the thread in a few seconds and without significant costs.

Commonly, you should use a tap and pass it back into the hole, or a die to clean the screw thread. This involves using taps or dies of the exact diameter and pitch to be restored.

The Nes, on the other hand, are designed to repair both internal and external threads and, thanks to the principle of their moving blades with a 60° or 55° angle, are suitable for all types of threads: M, MF, UNC, UNF, UNS, NPT, NPTF, ANSI, BSW, BSF, BA, G, BSP, BSPT, BSPP, PT, R, S, T, ACME, WH, RHT, LHT, F

Nes to restore Internal damaged thread  | Nes to restore External damaged thread  |

The Nes is available in 3 sizes for external threads and 9 sizes for internal threads, covering all diameters from 4mm to 108mm.

The Nes plays a similar role to a tap or die, as it has the same cutting capacity, allowing the chips to be evacuated in front of the tool.

Additionally, Nes are designed to reach internal threads up to 25mm (1″) deep, which allows most damaged areas to be restored.

There is no need for a lubricant when operating a Nes, as the low cutting forces and limited amount of material removed do not generate heat or deformation.

However, when working with ferrous metals and alloys, a light oil or fluid can increase the cutting speed and improve the finish

Advantages of Nes tools

A single Nes repairs damaged threads of different sizes. For example, an internal Nes 1 repairs damaged threads from 4 to 19 mm, an internal Nes 2 repairs damaged threads from 17 to 38 mm and an internal Nes 3 repairs damaged threads from 32 to 152 mm. In all the steps mentioned above.

Another strong point of the Nes is the possibility of being adapted also to British threads (BSW, BSF, G) using blades with an angle of 55 degrees, unlike the metric and American ones (UNC, UNF, NPT) which have blades with an angle of 60 degrees.

The Nes is particularly advantageous when it comes to external threads, because it is able to follow the original groove of the thread, maintaining concentricity and restoring any damage caused by wear, rust or chemical etching.

Provided there is an undamaged section of thread, the Nes can remove melted or dented material, improving the finish and surface integrity. This is one of the main advantages of the Nes over a traditional die, which tends to damage the crest of the original threads. Dies, due to wear or non-roundness, may not follow the plane of the original groove correctly, risking further damage of the thread. The Nes, on the other hand, maintains the original axis thanks to its ability to follow the existing groove.

Be careful though, Nes tools repair and clean slightly damaged, rusted or painted threads, cleaning the crests of the thread, but they do not recreate or reinforce completely or seriously destroyed threads, as Helicoils or Self-tapping inserts do. In fact, Helicoils guarantee greater resistance, even for small damages, and are the right choice when it is essential that the thread is perfectly restored, but only in internal threads

How to use Nes

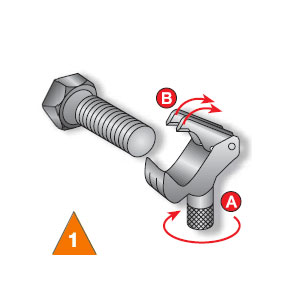

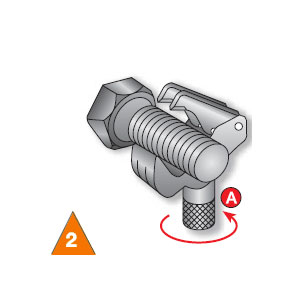

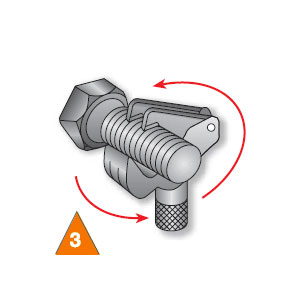

Repair of External damaged threads

Rotate the handle (A) to raise the floating blades (B)

Place the tool on the damaged thread to be repaired

Rotate the handle (A) to lower the blades into the grooves of the thread. Rotate the tool in the direction indicated to repair the damaged thread

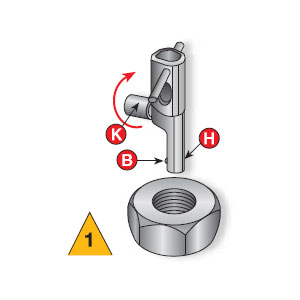

Repair of Internal damaged threads

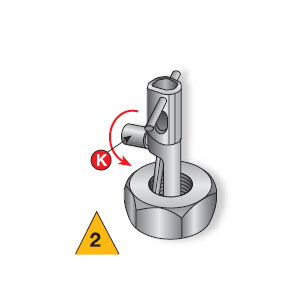

Rotate the knurled knob (K) to fully retract the blade (B) into the housing (H) and insert the tool into the threaded hole to be repaired

Rotate the knob (K) to extend the blade into an undamaged section of the thread and tighten by hand

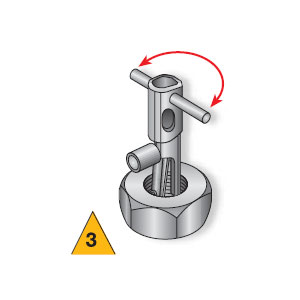

Use the cross rod to rotate the tool in the desired direction and repair the thread

Nes and other solutions for restoring threads, how to make the right choice

To repair a damaged thread, it is important to choose the right tool depending on the type of damage and the result you want to achieve.

If the thread is heavily damaged and needs to be recreated or reinforced, tools such as Helicoil inserts or self-tapping inserts Ensat or Keensert, are certainly more suitable for a restoration in accordance with the original specifications.

If, on the other hand, it is a minor damage or if you need to clean the crests of a thread, the ideal choice is the Nes, as an alternative to traditional taps and dies

Helicoil: Repairs damaged Internal threads

Helicoil inserts are one of the most common solutions for repairing severely damaged internal threads. These are thread inserts that not only repair, but also reinforce and recreate a thread as good as new.

The process involves the use of a specific thread insert tap to prepare the seat for the insertion of the thread insert. Once installed, the Helicoil creates a robust thread that is stronger than the original.

This solution is perfect for repairing internal threads in critical applications where strength and tightness are essential. If the damage is significant or you want a result that complies with the regulations, the Helicoil is the ideal choice.

Keep in mind, however, that each thread size requires a specific Helicoil tap and installation tool.

Additionally, Helicoils are intended for internal threads only, so you will need to use other tools, such as the die or Nes, to repair external threads.

For more details on thread inserts and their use, read the article Repair damaged threads with Helicoil

Self-tapping inserts: Even more robust repairs

If you need an even more resistant repair, or if the hole is much larger than the screw, you can use Self-tapping inserts

These are rigid metal inserts that, once installed, guarantee a solid repair especially in industrial or mechanical environments where superior performance is required

Restore damaged threads with Nes

If the thread has minor damage, such as crest dents, surface wear, or oxidation, you can use more versatile tools like the Nes to restore both internal and external threads. Few tools cover the entire range of sizes and pitches on the market

Taps and Dies: Traditional tools

If you prefer more traditional tools, Taps and Dies are another solution, but they require a specific tool for each size and pitch, making them more expensive.

In addition, a tap cannot restore threads like a Nes, because it cannot follow the original path of the cutting tool. Similarly, a die does not work like a Nes, because it risks damaging the crest of the original threads

So, how to choose the right tool?

Helicoil wire thread Inserts or Self-Tapping inserts are perfect for repairing severely damaged or completely destroyed threads, ensuring a robust repair that meets specifications

Nes is a universal tool, ideal for cleaning the crests of a male or female thread due to its versatility and ability to maintain the concentricity of the existing thread

Taps and Dies offer precision, but require specific tools for each size and do not guarantee the same restorative capacity as the Nes

As you may have understood, there is not a right solution for all cases, but your choice must be based on the extent of the damage and the result you want to achieve.

Consult here the complete Catalogue and the Technical Data Sheets of the products that you find available online. All popular sizes both metric and inch are in stock